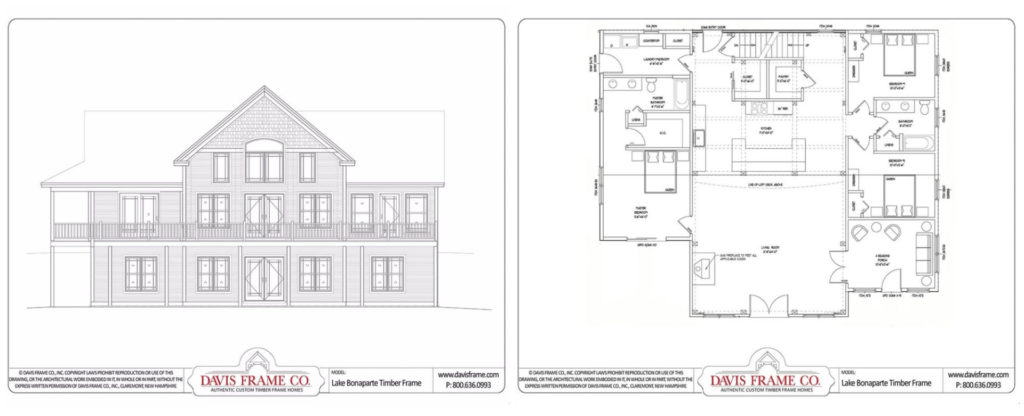

Check out our latest timber frame project under construction, a new hybrid timber frame home being built on Lake Bonaparte in New York! The homeowners met our Northern New York former Independent Representative Brian Morrow and builder Randy Nicol at a local home show last Spring. Together with Davis Frame, we worked as a team to design and fabricate this new Lake Bonaparte New York timber frame for them! We took the homeowner’s ideas and created a custom design featuring a center section 24’x40′ timber frame wrapped with Structural Insulated Panels (SIPS). The bedroom wings will be stick framed on site. Check out the floor plan below!

The main floor features a large 21’x24′ great room and opens up into the kitchen. To the one side of the great room is a small sitting area. On the opposite side is the spacious master bedroom suite. Two guest bedrooms with a shared bathroom is also located on the right-hand side. While the main living is on the first floor, there is an open 24’x24′ loft on the second floor which is a great flexible space that the homeowners will have. The loft offers a gorgeous view, looking through the timbers and out to the lake. The home design also features a walk-out basement. It’s designed as an unfinished space but could easily accommodate additional guest bedrooms.

A Day In The Shop

Perhaps the most exciting part for many homeowners is to see their timber frame home being crafted in our shop. The Douglas Fir timbers start out by being planned on our Hundegger planer. Nex, the timbers are ready to be cut using our Hundegger K2. The K2 is an amazing CNC machine that cuts the timbers to size and cuts the joinery. After each timber goes through the K2, our craftsmen fine-tune the joinery using chisels and there is also some hand sanding that is done to perfect the smoothness. After the handwork is done on the timbers, we often apply a clear coat of tung oil, which helps to bring out the grain of the wood and adds a protective layer to the timber. Below is a collage showcasing this timber frame in production!

The Timber Frame Raising

Once the timber frame is done in our shop, we ship it via flatbed trucks to the job site. The builder, Randy Nicol and his crew are featured here building the timber frame on site. This is Randy’s second Davis Frame timber frame, so he and his crew were familiar with raising the frame. With our timbers being pre-cut, it makes for a fast install! Typically, our frames can be raised within 3 days depending on the size of the job.

After the timber frame was raised into place, Randy and his crew worked on installing the loft floor system. Next, after the second-floor system, the crew got to work installing the Structural Insulated wall panels (SIPS). After the wall panels are installed, the crew will work on the 1×8 tongue and groove pine decking (T&G) that will be added to the roof of the timber frame. Following the installation of the T&G, the SIPS roof panels will be installed. Following the roof panel installation, Randy and his crew will build the stick frame wings on site. Check out the progress so far below!

Be sure to check back for more updates on the construction progress or visit our website for more photos of the Lake Bonaparte New York timber frame project! Interested in learning more about Davis Frame Company? Call us today at 800.636.0993!