Home Style: Panelized Homes

Why Choose This Option?

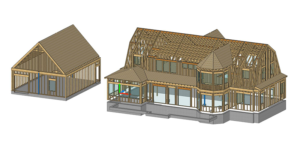

Distinctly different from our timber frame home and hybrid timber frame homes, our panelized home is a departure from timber frame methods completely. Our panelized homes instead use high-quality panelized wall systems, completely prefabricated in our facility and installed on site. A great alternative to timber frame or conventional construction, our panelized system saves construction time and on-site waste and are more budget friendly when compared with timber frame.

Compare with Hybrid Home Package and Timber Frame Home Package.

Standard Panelized Home Package

At Davis Frame, we offer flexible package options, but here is generally what is included in our standard structural conventional panelized packages:

PANELIZED WALL PACKAGE OPTIONS:

- Conventionally prebuilt panelized exterior walls

- Engineered roof trusses or precut 2x rafters for roof

- Various sheathing options for walls and roof

- Floor framing

BUILD-PAK PRECUT SHIPPED “LOOSE” OPTION

- Pre-cut ready to assemble conventional framing components packed and organized into intuitive bundles

- Various sheathing options for walls and roof

- Floor framing

- Windows and exterior doors

- Siding and trim

- Pine or spruce tongue and groove decking

What are the Benefits of a Panelized Home?

At Davis Frame, we developed our high-quality and precise systems-built panelized wall system to offer homeowners and builders a high quality and faster way to build a new custom home. It is a great alternative compared to conventional building methods.

PRECISION MANUFACTURING

FASTER ON-SITE CONSTRUCTION

Our prebuilt panelized wall panels and precut roof will drastically cut down the framing time on site. One of our panelized packages can be assembled in as little as 2 weeks.

MINIMIZED ON-SITE WASTE

With our panelized wall system, there is minimal to no cutting involved, which also cuts down on jobsite waste.

Difference Between Panelized & Conventional Framing

As you research new home construction, you will come across systems-built construction methods as well as conventional on-site framing. Let us explain the difference.

SYSTEMS-BUILT OR “PANELIZED”

- Factory controlled for optimal quality and precision

- Straight plumb walls for easier finish work

- Accuracy down to 1/16”

- Accurate structural package cost

- No overages or mis-cuts

- Reduced waste on-site

- Less carpenters needed for installation

- 2-4 weeks to frame depending on size

- Less weather delays due to faster on-site installation

CONVENTIONAL FRAMING OR “STICK-BUILT”

- Exposed to weather elements, potentially diminishing quality

- More prone to weather delays

- Not always square

- Hard to achieve 1/16” accuracy

- Varying costs and potential back charges

- Overage and mis-cuts

- Site waste

- Labor shortages making it a challenge to find builders

- 2 months to frame depending on size

We’ve had the unique pleasure of working with Davis Frame on some amazing homes. What sets their team apart is the collaborative approach and willingness to design a home that is exactly in alignment with the client’s vision.